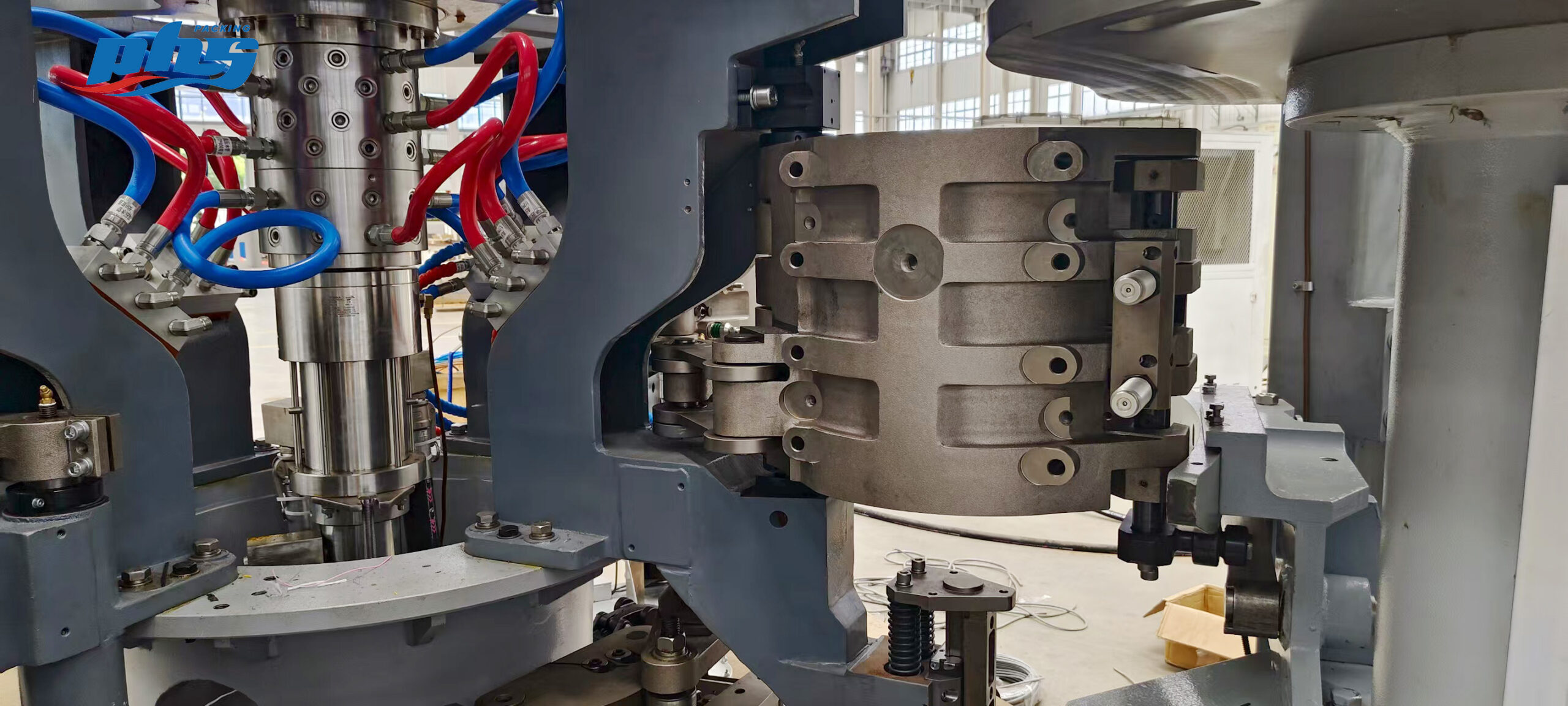

Blowing System

This series of automatic bottle blowing machine is developed by our company. It has the characteristics of simple and convenient operation, high stability and high yield.

The heating furnace has designed a bottle body turnover mechanism. After the bottle enters the heating furnace, the bottle mouth is downward through the turnover mechanism, heated by the infrared lamp in the furnace, and then turned over again before leaving the heating furnace to enter the main blowing wheel. The main purpose is to protect the bottle mouth, which is not easy to deform during the heating process. After the bottle mouth is turned down, the bottle mouth is well protected from deformation by shading plate, cooling water channel and fan, At the same time, it can save energy than the heating furnace without turning over. At the same time, the specially designed ventilation cooling device and protective plate cooling water in the heating furnace are used to prevent the furnace temperature from being too high and the special air duct is used to cool the thread part of the billet pipe. The cooling air is controlled by the frequency conversion fan, and any wind force can be adjusted to keep the furnace temperature constant and prolong the life of the infrared lamp tube;

Filling System

1) Filling realizes the filling of water into the washed bottles sent by the bottle washing machine. The bottle entering the filling machine is held by the bottle neck supporting plate stuck at the bottle mouth. Under the action of the lifting rod driven by the cam, the bottle can rise to contact the filling valve. After the filling valve is opened, the filling process is gravity filling. When the liquid level reaches the height of return pipe, the filling will be stopped automatically. At the end of filling, the lifting rod descends under the action of the cam to make the filled bottle leave the filling valve, and the bottle enters the capping machine through the transition wheel of the bottleneck.

2) The filling machine is designed and manufactured by our company by introducing foreign technology and using the principle of atmospheric vacuum filling.

3) The filling valve adopts gravity type mechanical valve, which can fill quickly and sensitively, and can be used for CIP cleaning inside the valve.

4) The bottle lifting adopts double guide rod structure, which makes the bottle lifting, centering and descending more stable.

5) The material in the filling cylinder is controlled automatically, and the liquid level is detected by the liquid level sensor to ensure the stable liquid level and reliable filling.

6) The key parts and electrical components of the machine are imported products.

Capping System

The anti rotation knife on the capping machine is stuck at the bottleneck to keep the bottle upright and prevent rotation. The capping head keeps revolution and rotation on the capping machine. Under the action of cam, the capping, capping, capping and decapping actions are realized, and the whole capping process is completed. The finished bottle is transferred from the capping machine to the bottle delivery chain through the bottle out paddle wheel.