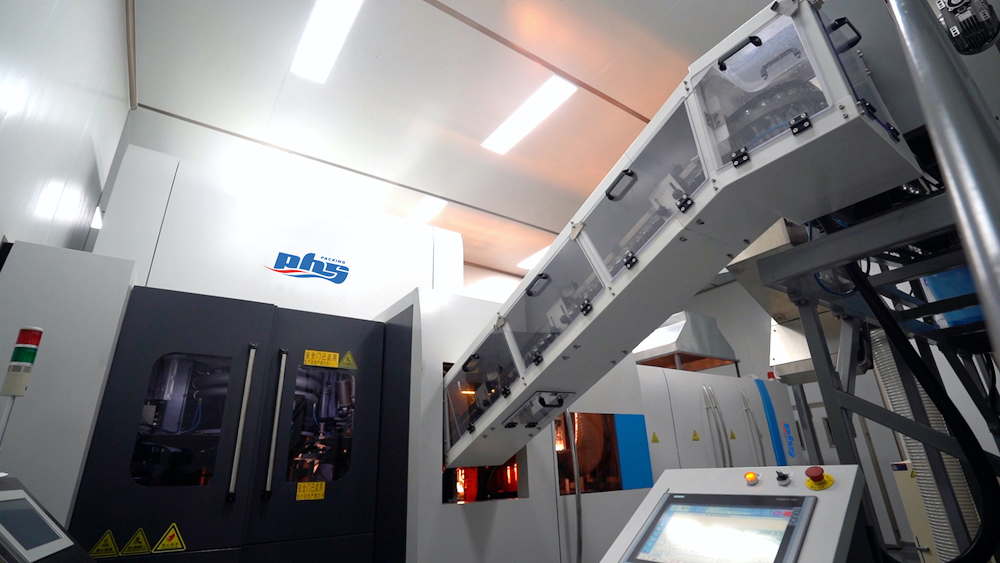

Blowing-Filling-Capping

Combiblock

which has the advantages of simple operation, stable and efficient, low energy consumption and high degree of intelligence.

The Blowing-Filling-Capping Combiblock is one powerful combination, which completes the whole process from preform to bottled, It can decrease intermediate links such as conveying, empty bottle handling, stacking and storage processes, improve packaging sanitary conditions, reduce cross-contamination, increase overall operating efficiency, save energy consumption, so that it cuts overall production costs.

PHS integrates the industry’s most cutting-edge bottle blowing and filling technology to complement each other’s advantages. At the same time, we fully absorbed the core technology of COMAN to design and manufacture our own core product, the CGX series Combiblock which is simple to operate, stable and efficient, low energy consumption, and highly intelligent.

The production types range from small bottles (100ml) to 19L in barrels, and the production capacity per hour ranges from 2000 barrels (19L/B) to 54,000 bottles (500ML/B).

| TYPE | BOTTLE SIZE | CAPACITY |

| Drinking Water Filling | 0.5-2L | 12000BPH-54000BPH |

| 5L | 4000BPH-6000BPH | |

| 15L | 1500BPH-3600BPH | |

| CSD Beverage Filling | 0.33-2.5L | 5000BPH-48000BPH |

| Hot Filling | 0.5-1.5L | 5000BPH-48000BPH |

| Ultra-clean Filling | 0.5-1.5L | 12000BPH-48000BPH |

| Aseptic Filling | 0.5-1.5L | 12000BPH-48000BPH |

- Combiblock for Disposable Barreled Drinking Water

- Combiblock for CSD beverage

- Combiblock of Hot Filling

With the improvement of people’s living standards, the healthy drinking water consciousness gradually roots consumers. Cooking water, tea with water … More and more consumers tend to bottled&barreled water, large-capacity packaging water sales is increasingly smooth.

However, the barreled water market , the water market has long been a single product model.

In order to solve the current difficulties and pain points in the barrel water industry, PHS in the technology frontier is first to introduce a disposable PET material to the market, We have tailored the production line of disposable barreled drinking water for many customers, such as 12L for Nongfu Spring, 15L for Robust.

- Compatible with 5L-19L

- Filling Method: Gravimetric Flow Meter, Photoelectric Detection.

- Production capacity: 1200BPH-4800 BPH

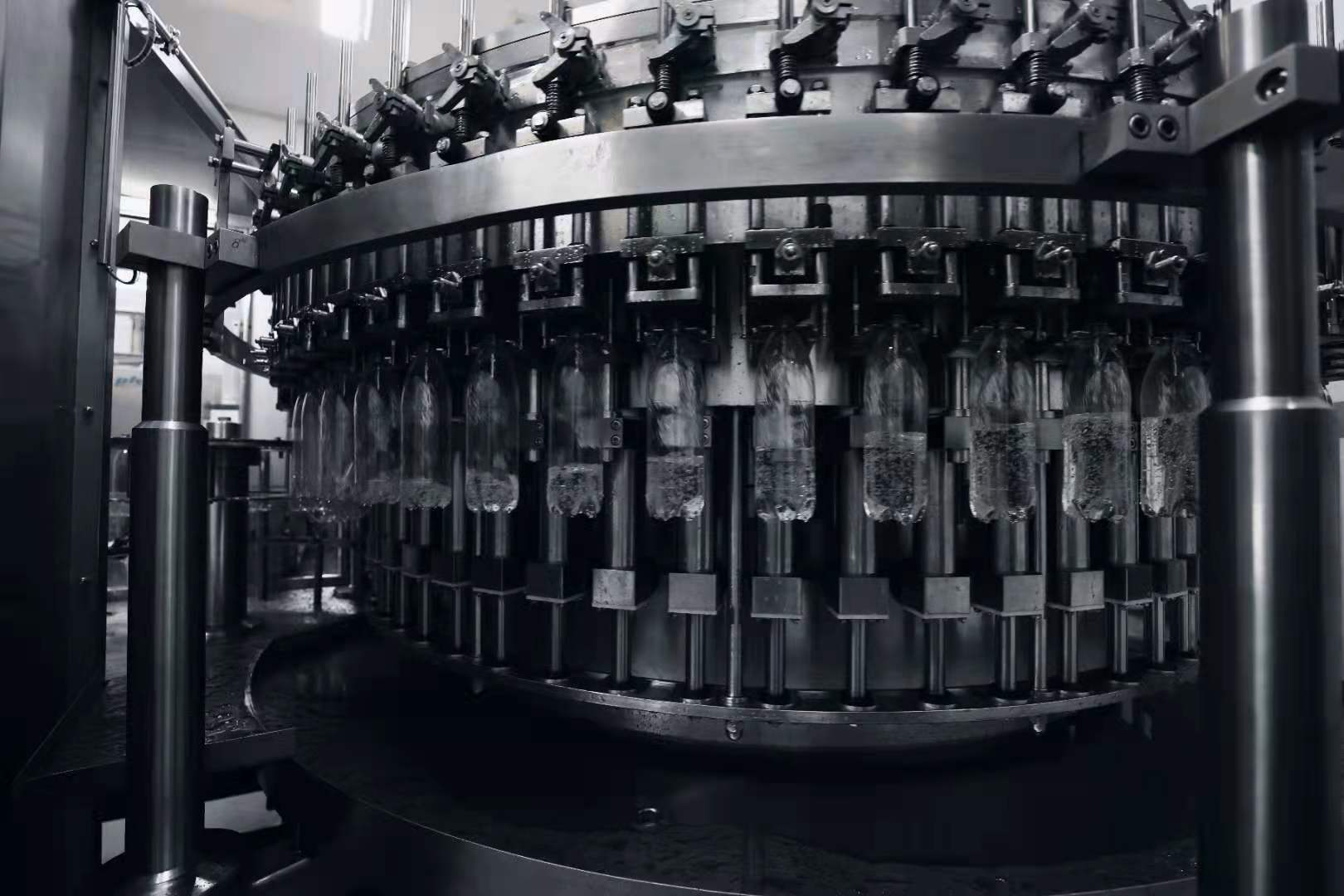

Blowing-Filling-Capping Combiblock for CSD beverage integrates the blowing, filling and capping technology and applies the servo system to synchronize control to achieve multiple unit devices integrated control and production, meet the production needs of various drinks, thereby reducing investment costs, energy consumption and maintenance costs, plus the perfect layout to achieve maximum energy consumption by 25%.

PHS Blowing Unit makes the PET bottle can hold the up to 4.2 times CO2 dissolved liquid.

PHS CSD Beverage Filling Unit combined with multi-year CSD beverage filling experience, make sure the filling stability, not Frothing, level uniform characteristics. Used with our CSD mixer, Combiblock can fill CSD beverage at high speed and stably, products high quality taste for beverage manufacturers.

Our customers have Coca-Cola, Pepsi, Jianli Bao (YUANQI SENLIN), Arctic Ocean, etc.

- Filling Method; Mechanical Valve Filling, Flow Meter Filling, Electronic Valve Filling

- Capacity; 12000BPH-48000BPH

- Filling Temperature; 0-4° or 12-15°

- Soda Water, Sparkling Water, Cocktail, Flavored Water…

Mainly used for Filling&packaging PET Bottle of Juice, Tea Drink, Energy Drink, Functional Beverage and etc.

Capacity: 9000BPH-48000BPH

More Cases & SolutionsPACK WHAT YOU WANT

World Class Quality

PHS component configuration is based on the TOP quality components of world recognized in the liquid packaging industry, The devices are designed in compliance with EU safety and CE-marked

Lenze, B&R, SEW, DANFOSS, SIEMENS, FESTO, AAF, SKF, INA, NSK, SICK, PHENIX, MULL, OPTEX, BELLI, TRELLEBORG, RJW, SEITZ, REXROTH, METALWORK,E+H, TE, etc.