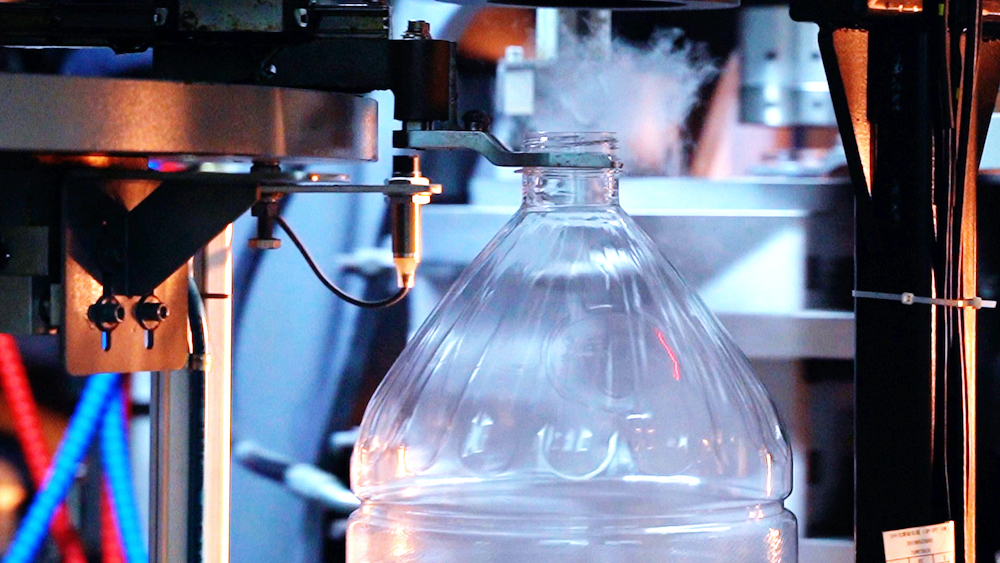

The blow molding machine first heats the PET preform, and then stretches and blows it with compressed air in the mold, in line with the development trend of high-speed beverage production lines, fully automatic rotary blow molding machines have gradually become the mainstream and are widely used by large and medium-sized beverage companies.

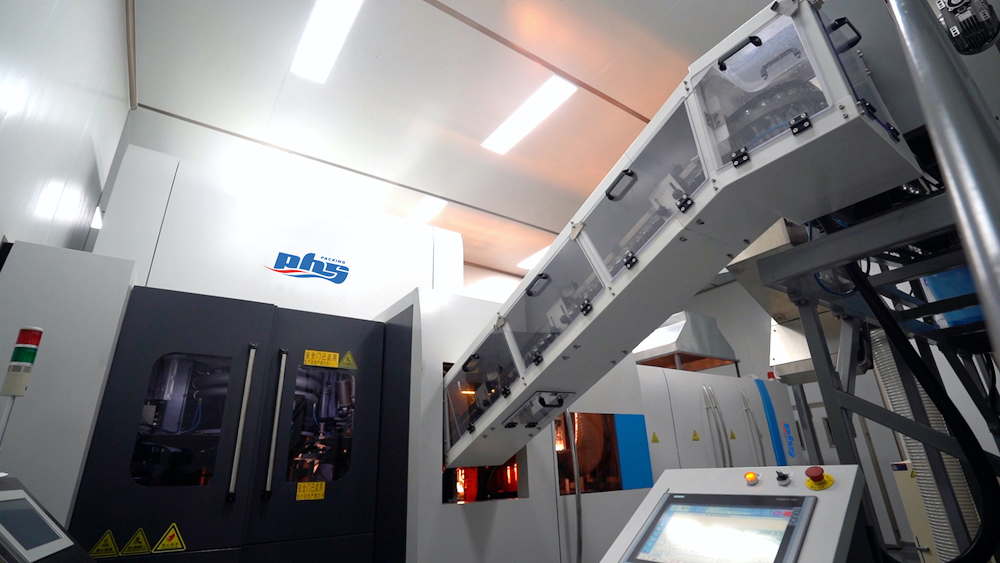

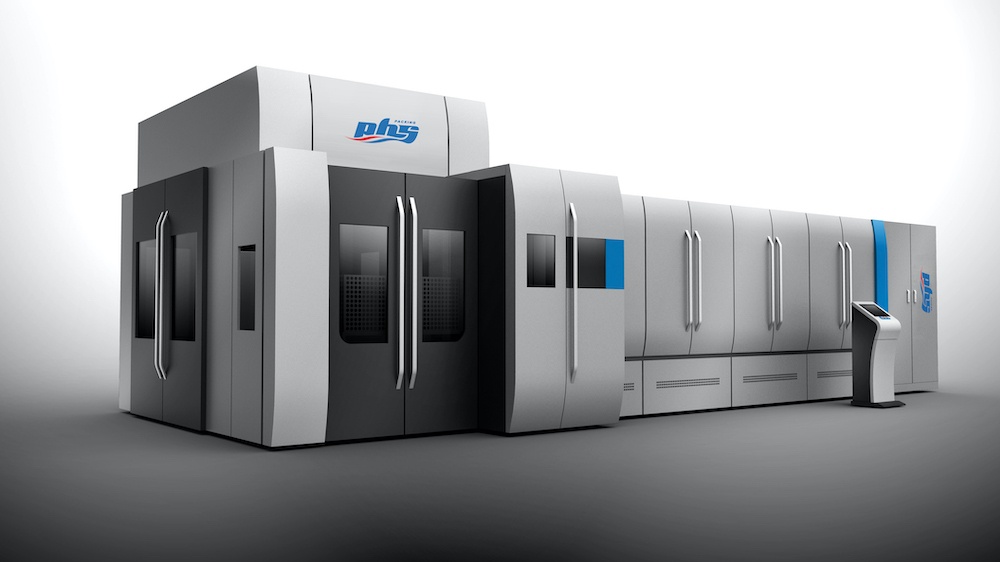

In 2015, PHS acquired a company specializing in manufacturing blow molding machine packaging equipment for more than 15 years, and established a subsidiary-PUQIA Blow Molding Technology Co., Ltd. A team with more than 30 professional high-end technical talents in automation control, mechanical design and process design has been formed, focusing on the R&D and manufacturing of rotary blow molding equipment, at the same time, we formed PET mould Division specializes in bottle design, and the entire line adopts the American Haas CNC machining center.

More than 350 units have been delivered statistics until December 2020, PUQIA rotary blow molding machine has reached the industry’s leading advanced technology level. With automation, high intelligence, stable and reliable performance, high efficiency, energy saving, safety.

PUQIA rotary blow molding machine is used in the production of PET bottles for beverages, milk products, wines, condiments, medicines, daily chemicals, etc.

Varieties

- Standard SERIES Size; Bottle Size, 0.25-2.5L

- Singe Serve SERIES; Bottle Size, ≤0.77L

- Large SERIES; Bottle Size 3-19L

- Aseptic PET SERIES

Single Cavity Capacity

- 2500BPH/Water Bottles,

- 2000BPH/CSD Bottles,

- 1200BPH/Hot Fill Bottles;

Tailor Complete Solutions &

Turn-key Projects

We are committed to providing our customers worldwide with integrated innovative solutions capable of fully meeting their demands for liquid filling&packaging production and storage in efficiency, reliability, flexibility and energy saving.