What are the Benefits of a Bottle Blow Molding Machine?

It’s frustrating when your business can’t meet the demand for its products. What if a single machine could help you produce thousands of bottles quickly and efficiently?

A bottle blow molding machine offers many benefits, including cost-effectiveness, high production speed, design flexibility, and seamless part creation. It also enables mass production and automation.

If you’re looking to improve your manufacturing process, keep reading to discover more about blow molding machines.

What is the use of bottle blowing machine?

Ever wonder how all those plastic bottles get made? Are you struggling to keep up with the demand for your beverage or other liquid products?

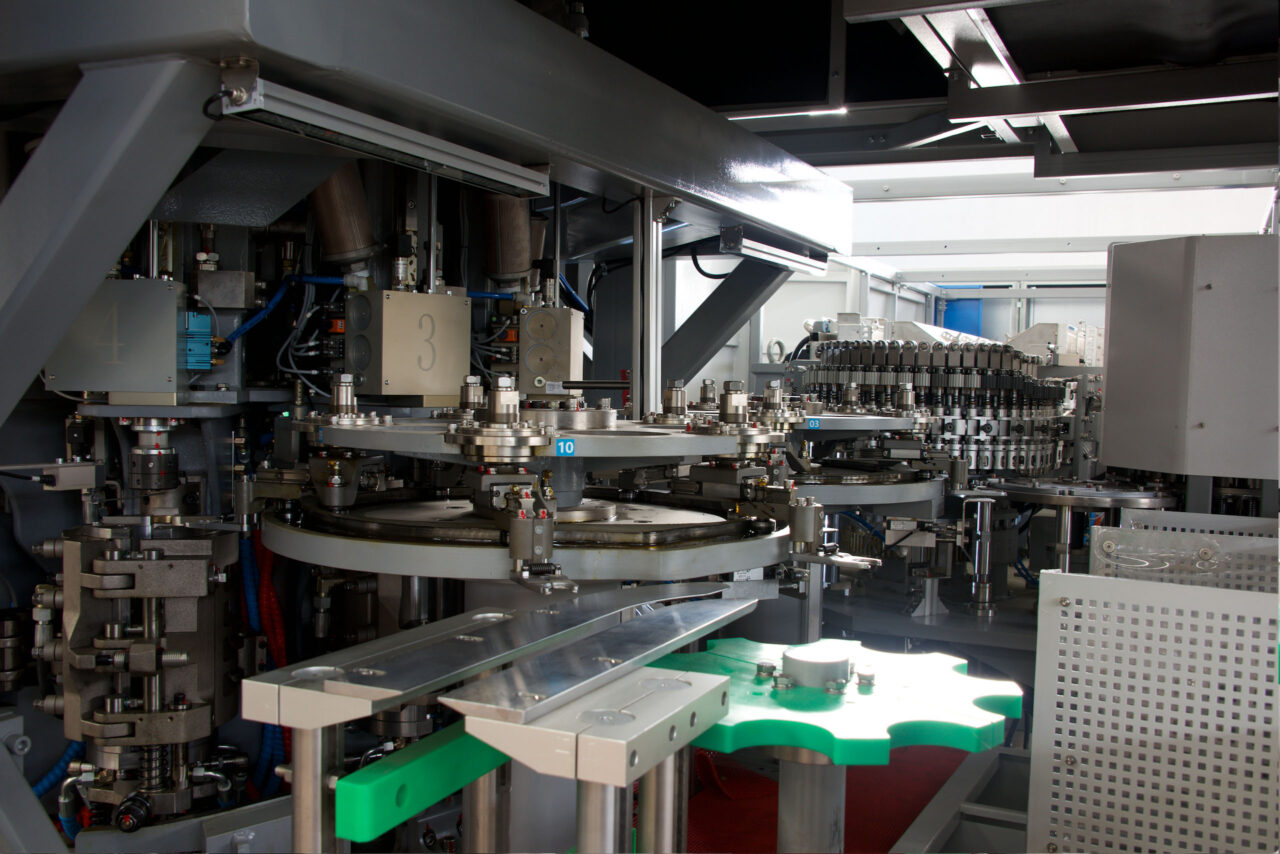

A bottle blowing machine is used to produce plastic bottles and containers. It shapes molten plastic into specific forms by inflating a plastic tube, called a parison, inside a mold.

Blow Molding Machine Uses: Dive Deeper

Types of Plastics Used

Bottle blowing machines can work with different types of plastics, including:

| Plastic Type | Properties | Common Uses |

|---|---|---|

| Polyethylene Terephthalate (PET) | Strong, transparent, and recyclable. | Water bottles, beverage bottles, food containers. |

| Polyethylene (PE) | Flexible and chemical resistant. | Milk jugs, detergent bottles, grocery bags. |

| Polypropylene (PP) | Rigid, heat-resistant, and chemical resistant. | Yogurt containers, medicine bottles, and food packaging. |

| Polyvinyl Chloride (PVC) | Rigid and can be made flexible with additives; resistant to chemicals and weathering. | Pipes, window profiles, and some bottles. |

Blow Molding Process

The bottle blowing process generally involves these steps:

- Preform Creation and Heating: A preform, usually made of PET, is heated to the right temperature.

- Molding and Shaping: The heated preform is put into a mold that determines the bottle’s final shape and size.

- Blowing: High-pressure air is used to inflate the preform against the mold walls.

- Cooling and Ejection: The bottle is cooled to harden, and then ejected from the machine.

I remember the first time I saw a bottle blowing machine in action. It was at a beverage factory in China. The speed and precision of the machine were impressive. It quickly turned out perfect bottles, ready to be filled and shipped.

Why is blow moulding used for bottles?

Are you looking for a cost-effective and efficient way to produce plastic bottles? Do you need design flexibility for your packaging?

Blow molding is used for bottles because it’s cost-effective for large-scale production, allows for complex shapes, and creates seamless, hollow products. It also works with many types of plastics.

Blow Molding Advantages: Dive Deeper

Cost-Effectiveness

Blow molding is cost-effective because:

- It reduces material waste by using only the necessary amount of plastic.

- It has fast production rates, making it suitable for mass production.

- It requires less labor due to its automated nature.

Compared to other methods like injection molding or rotational molding, blow molding requires fewer resources. This is especially important for large containers, where material costs can be significant. Blow molding machines can also recycle and reuse excess plastic, further reducing waste.

Design Flexibility

Blow molding offers flexibility in design because:

- It can create complex shapes, including those with handles or indentations.

- Custom molds can be used to meet specific design needs.

- It allows for unique shapes and sizes to meet different market demands.

Seamless Parts

- Creates hollow, seamless products without needing extra assembly.

- Reduces the risk of leaks or weak joints.

- Ensures airtight or watertight containers.

What is the purpose of the molding machine?

Are you curious about the key to producing top-quality products in manufacturing? Do you want to know how raw materials are transformed into intricate forms?

A molding machine shapes raw materials into specific forms and designs. It’s essential for making many products, from household items to automotive parts. Molding machines use pressure, heat, and precision controls to accurately and consistently transform raw materials into finished products.

Molding Machine Role: Dive Deeper

Types of Molding Machines

Molding machines come in different types, each designed for specific uses:

| Machine Type | Use | Examples of Products |

|---|---|---|

| Injection Molding | For producing plastic parts by injecting molten plastic into a mold. | Bumpers, dashboards, syringes |

| Blow Molding | For making hollow plastic products by inflating a parison inside a mold. | Bottles, containers |

| Rotational Molding | For creating large, hollow parts by heating and rotating a mold filled with plastic. | Storage tanks, kayaks |

Key Functions

Molding machines must perform the following functions:

- Loading and Positioning: Properly load and position materials.

- Filling: Fill the mold with the required material.

- Compaction: Solidify the material.

- Ejection: Remove the finished part from the mold.

What are the advantages of molding?

Are you looking to produce detailed and complex plastic parts efficiently? Do you want to minimize material waste and reduce production costs?

Molding offers the ability to produce detailed and complex geometries, ensures strength and versatility, allows simultaneous use of multiple plastics, and provides cost savings through efficient production and minimal waste.

Advantages of Molding: Dive Deeper

Detailed and Complex Geometries

Molding allows you to create highly complex and detailed plastic parts in large volumes with almost no deviation. This is achieved through precise tool design and process optimization. With the right approach, you can produce parts that meet very specific requirements.

Strength and Versatility

Plastics used in molding are strong and versatile, capable of withstanding harsh environments. There are many engineered materials to choose from for complex applications. High-performance blends and hybrids can also be formulated to meet specific part needs.

Cost Savings

Molding reduces material waste, which lowers production costs. It also allows for high-volume production, further reducing the cost per part. By optimizing the molding process, businesses can achieve significant savings.

One of my clients, a beverage company in North America, significantly reduced their production costs by switching to a more efficient molding process. They were able to produce bottles faster, with less material waste, and with consistent quality. This helped them stay competitive in a tough market.

Conclusion

Investing in a bottle blow molding machine can significantly improve your production process. It offers cost-effectiveness, speed, design flexibility, and seamless part creation. With the right machine, your business can meet high demands and stay competitive.